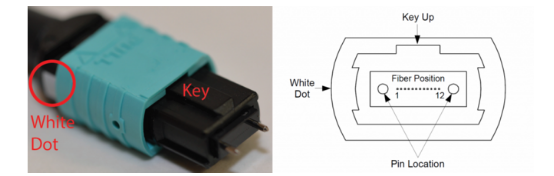

MTP/MPO connector factory terminated assembly can house 6 to 72 fiber array, with 12-fiber and 24-fiber arrays being the most common. There are now 8 and 16 single row fiber types that can be stacked together to form 24, 36 and 72 fiber connectors using multiple-precision ferrules. In fiber orientation, each of the fiber holes in the connector is numbered in sequence from left to right. We will refer to these connector holes as fiber position, or P1, P2, etc. Each connector is additionally marked with a white dot on the connector body to denote where the position 1 is when it is plugged in(shown in the following picture). The orientation of this key also determines the MPO cable’s polarity.

The TIA spec for cabling (TIA-568) has more than 20 pages of possible combinations for MPO cable plants, varying in pins/no-pins, keying, types of connectors, color codes and numbering schemes. To understand the issues, above all, we should start with the standard fiber color codes. Terminated in an MPO connector logically and per industry convention, where the connector pins are also numbered 1-12, you would have a connector like this:

Polarity in MPO cables

Polarity simply refers to the way fibers are arranged inside the cable. TIA 568 standard defines three methods for MPO polarity which are Type A (commonly called Straight-through), Type B (commonly called Rollover), and Type C (commonly called Twisted-pair). We can say that the polarity in MPO/MTP fiber optic cables is the same as the concept of straight through, crossover, and rollover for copper cables(UTP & TP). Let us have a look into each of this in detail,

Type A (Straight-through) Cables

Straight-through cables get their name from how they are made. Out of the 12 pins that exist on both ends of an MPO cable, each pin connects to the same pin on the opposite side. Or we can say that the fiber located at position 1 (P1) on one end also arrives at P1 on the other end,

Straight-through MTP/MPO cables are used mostly for connecting patch panels. They are primarily used for connecting, unlike devices. A straight-through MTP/MPO cable is typically used in the following situations:

· Connecting a computer to a switch

· Connecting a LAN port to a switch, transceiver, or computer

Type B (Inverted or Rollover) Cables

Rollover cables essentially have one end of the cable wired exactly opposite from the other. This essentially “rolls over” the wires- but why would we need to do such a thing? Rollover cables, usually connect a device to a router or switch’s console port. This allows a programmer to make a connection to the router or switch, and program it as needed. The fiber located at P1 on one end arrives at P12 at the other end.

Type C (Twisted pair or Crossover) Cables

Crossover MTP/MPO cables are very similar to straight-through MTP/MPO cables, except that they have pairs of wires that crisscross. This allows for two devices to communicate at the same time. Unlike straight-through cables, we use crossover cables to connect like devices. The fiber located at P1 on one end arrives at P2 on the opposing end, P2 arrives at P1, and so on for each pair of fibers.

Crossover cables are typically used in the following situations,

· Connecting a computer to a transceiver

· Connecting a computer to a computer

· Connecting a switch to a switch

Type A and B are the most common types of polarity used in data centers and CORDs while Type C is more typical of duplex applications. However, no one polarity type is better than another. Knowing which is appropriate depends on your architecture’s design. Different equipment manufacturers or applications might require different polarity types.

Importance of polarity validation

Why is it important to validate polarity? Your main goal is to make sure the right transmitter (TX) goes to the right receiver (RX). To accurately send and receive data, it is critical that MPO connectors be properly aligned and mated. The bad coupling will impede signal transmission, as the signal could be sent in the wrong direction.

It’s also important because a single cable with a polarity type different from the rest can change the polarity of the entire link. For example, if all your elements are Type A (cable, mating adapters, etc.), but one element is Type B, then the whole link becomes Type B. As a rule of thumb, Type A elements maintain the polarity, while Type B elements will reverse the polarity.

Moreover, when working with a fanout cable, it’s important to be aware of polarity to make the right connections, or you could end up with a different polarity type.

Undiagnosed polarity issues increase Capex and work for technicians (i.e. opex). Technicians may unnecessarily rip and replace expensive short-distance MPO patch cords they falsely believe are faulty, but in fact, did not have the correct polarity type. If polarity issues are not corrected before turn-up, then it’s a frustrating and tedious guessing game to try to pinpoint which cable connections have polarity problems after they have been installed.

Choosing tools that can validate and clearly identify polarity is essential. Ensuring accurate polarity for MPO fiber array cables is a big deal, and can be complicated to manage due to multiple polarity schemes available for these connectors, and polarity flipping during connection and installation. It becomes even more complex with new flexible MPO connectors that allow field reconfiguration of polarity and gender. Polarity validation is proving especially critical with these new MPO connectors that enable polarity reconfiguration in the field. Be sure to equip your team with solutions that can validate both 12- and 24-fiber cables to avoid unnecessary CAPEX.

That's not the end. Features and uses of MPO/MTP cables are much more. Read through Article 3 to know more.

Have a comment or points to be reviewed? Let us grow together. Feel free to comment.

Well-written overview of fiber row configurations in MPO connectors. This knowledge supports better planning and deployment in data centers, especially for Structured Cabling UAE environments.

ReplyDelete